- Company Profile Chairman's Speech R & D Team Honor Development History

-

To be the most satisfactory energy and environment company in the world

To be the most satisfactory energy and environment company in the world

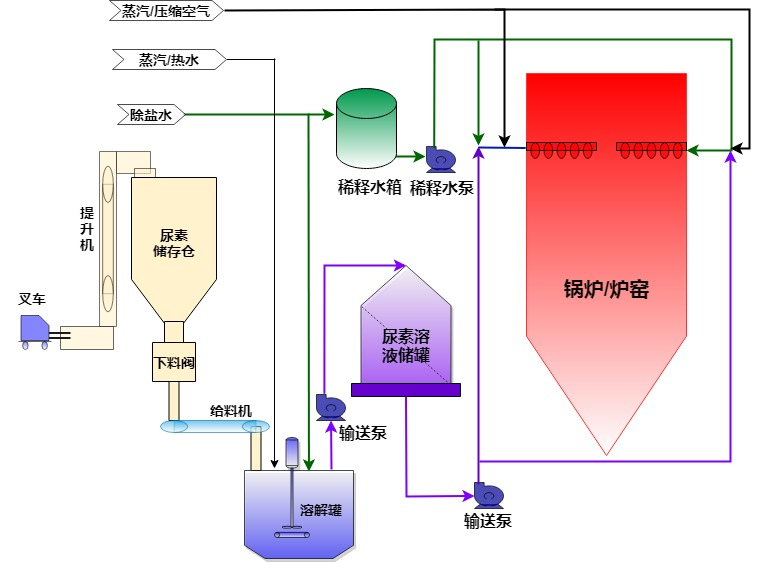

- Environmental Protection Clean Energy Renewable Energy

- Company News Video Dynamics

- Impression Party Group Building

- Contact Us